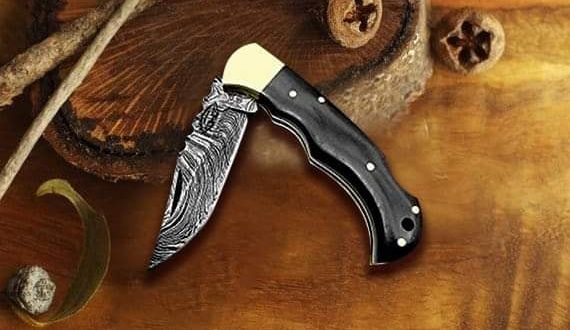

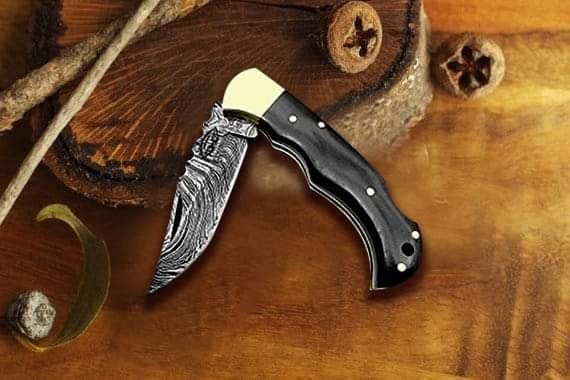

Damascus Steel or “Pattern Welding”

Welding with style is the practice in the manufacture of the sword and the blade from the structure of the cutting pieces. Some pieces of metal of different pieces are manufactured welded and controlled to control the style in the traditional Custom Damascus Knives. Often, the pieces of loaded steel made in this way seem to be quite different groups of forms along its length.

These groups can be distinguished for corrective purposes by cleaning or corrosive paint. The patterned weld was a coated or reinforced steel product, a similar procedure used to reinforce the steel of a distinctive carbon material, which provides a desirable blend of stiffness and strength. Although current steel making cycles refute the need to mix different types of steel, knife makers still use welded steel for unnecessary effects.

Procedure of pattern Welding

The welding pattern was created from a complex procedure, mainly for the manufacture of edges that were difficult and intensive of air performance and unacceptable when purifying it of iron in the decoration. Plum does not produce enough heat to liquefy iron and steel, but it reduces metallic iron oxide to unprepared iron particles, which are then welded to a mass of ground iron, which consists of pieces of contaminants in an iron network pure in general.

It is very delicate it is not possible to make a sharp edge adhere. The railings or sheets of soft iron are a layer of steel with high carbon content at first sight, and the early mature boards make these bars or panels join to form homogeneous steel bars in general. This type of distinctive steel covers designs that can be seen on the edge of the sharpened edge finish, which provides the basis for the welding pattern on the Damascus knife.

Pattern welding of Damascus Knives in Europe

In the 2nd and 3rd centuries AD, Alton used the welding pattern of cosmetics as part of the expansion for structural reasons. This included the collapse of the metal and the production of alternative steel layers in the columns, which would tend to build complex models when they are produced at the forefront. For the 6th and 7th centuries, the welding in the pattern reached a level where the thin layers of steel were placed in a center of fine iron, which led to a significant improvement since the iron provided them with a predictable and adaptable center. No sword blow blows to stop bending the edge of cut or attraction. Before the end of the Viking period, the welding pattern of use in Europe decreased.

In the middle of the Middle Ages, the knives from Damascus were delivered to India and returned to Europe. The similarities in the signs that they were the same methodology that they used, convinced the style of welding restored by the European blacksmiths who tried to copy these beautiful knives of Damascus. While the routines used by Damascus for its sharp edges have been lost, the late attempts of metal scientists and their blades to repeat steels with indistinguishable properties have resulted in a process that does not involve welding patterns. But even these efforts have not been a great achievement.

A comparative system was also used by the Scandinavian swordfish in the Middle Ages. Today’s Mora code is manufactured with a comparable strategy. Nowadays, normal steel is used from time to time, however steel with high carbon content is usually solid or stainless steel.

Show how to make a Custom Damascus Knife.

Ancient swords misused the characteristics of high quality welded steel. The Vikings were specifically fascinated by the curved steel rods that surrounded each other, joined them by beating and then went through the procedure with successive rods to present complex examples on the last steel bar. Make two bent rods in the backing pads of the regular Chevron design. Regularly, the core of the edge was concentrated in the sensitive steel, and the edges were strong steel with high carbon content, like the Japanese covers.

For example, the Smith Smith Blade smith Society in Master Smith requires a 300-degree lead. Large amounts of layers are created in large part by collapse. Some layers are sold together, then cut fifty-five times and then re-welded, with each process striking the number of layers. Starting with only two layers, eight breakouts will result in 512 layers appearing in light mode.

The sharp and barbed edge of such a clear cut will be very similar to a piece of wood, with arbitrary comparison elements, for example. Some materials can be reworked in soldier style spaces. The Damascus cable, made of a high-carbon multi-thread bond, is a prominent feature of plasmite adhesives, creating the example of a fine granular wound, while cutting machine chains creates an example of shadow spots arbitrary.

Other Welding Blades

Some of the current welding blades have taken the style to the new stents, with extensive applications of traditional blade welding procedures in Damascus, as well as a new innovation. A plate of steel bars with a sharp, clear and perpendicular slide with layers can provide some excellent examples, including mosaics or real compositions.

Powder metallurgy allows composite materials that are usually not good enough to be incorporated into solid bars. After cleaning and cleaning, several steel medicines, for example, dyes, scratches or other medicines for industrial surfaces that react paradoxically to the distinctive metals used, can make large high-quality differentials complete in the steel. Some expert experts invest in the use of procedures, for example, the electric cutting process to eliminate interlaced models of various steels, join them and then weld the next assembly on a strong piece of steel blades in Damascus

Universal Bloggers

Universal Bloggers