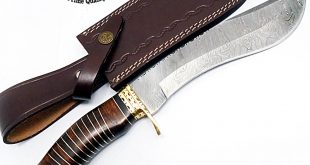

What makes Damascus steel Knives Extraordinary?

Damascus steel is a one of a kind ferrous material created by the Arabs in the homonyms city in Syria, up to half of the eighteenth century. It is unmistakable by an exceptional and charming botanical like example on the outside of the steel with a progression of glossy metallic groups and darker obscure ones, in similarity, in the event that you need, to the damascato texture.

Other than the wonderful optical impact it was and is outstanding and looked for after for consolidating a high hardness and a propensity to keep up its cutting capacity, and a high sturdiness (something contrary to delicacy which is the inclination to break upon sway). This mix of strength and hardness is the mantra of present day metallurgy and, even now, in 2015, with all the progressed systematic methods and significant metallurgical information, the insider facts covered up in Damascus cutting edges are not completely comprehended.

The steel was created from ingots imported from Sri Lanka and southern India known as Wootz steel. It is currently very notable that the minerals extricated in those districts didn’t just contain iron yet in addition carbide making components, for example, Vanadium and Tungsten (The Key Role of Impurities in Ancient Damascus Steel Blades). The nearness of little amounts of these components however isn’t itself adequate to legitimize the uncommon blend of mechanical properties. The microstructure of Damascus steel is portrayed by a fine mix of ferrite (alpha-iron) and cementite (Fe3C) lamellae (or just groups) got from progressive cycles of Forging and Quenching and strengthening comparable, or similar to, to the procedures utilized by the Japanese sword-creators to present a high hardness and durability to their kabanas. In this progression of warming, twisting, cooling, re-warming and misshaping lies the covered up, lost mystery of the generation procedure.

Albeit many have had a go at duplicating these systems, none have really figured out how to acquire a repeatable procedure to deliver the hardness and sturdiness blend and the botanical impact superficially. An ongoing discovery by a gathering at the University of Dreads, in Germany, in a correspondence on the lofty diary Nature has redone the fantasy of this steel joining it with the publicity for nano-materials. They found, in a unique Damascus saber delivered in the seventeenth century by the well-known metal forger Assad Ullah, endless supply of an example of the sword in hydrochloric corrosive, of cementite nano-wires perhaps ensured (?) via carbon nanotubes. I truly do not understand how they got to that end in the wake of perusing both the Nature correspondence and the paper on Acta Materialia (Atomic structures of iron-based single-crystalline nanowires solidified inside multi-walled carbon nanotubes as uncovered by expository electron microscopy) refered to legitimize the announcement and I’m very certain our Assad Ullah had positively no idea about nanotubes, all things considered, the news made it to National Geographic and Damascus steel, nanotubes and the University of Dreads were back on the communicational wave.

Universal Bloggers

Universal Bloggers